My fathers house has a moist basement. This causes rusting of metal beams inside of the basement and can potentially deteriorate structural integrity. To combat this we chose a comparatively cheap solution called “dew point drying”. A controller essentially automatically ventilates the basement when the water content of the air outside is lower than the water content inside of the basement air. To control this ventialtion we chose a window actuator. Without going too much into detail on how the window actuator operates, it basically had two inputs that needed to be pulled to GND for a short moment; A: Open the window and B: to close it.

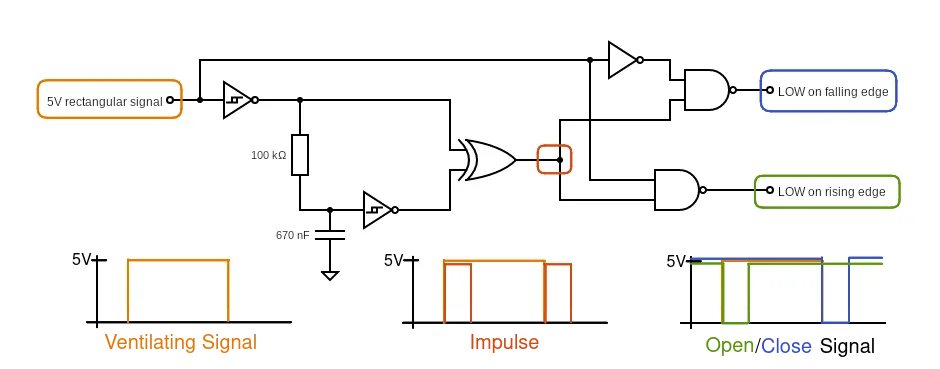

I got a bit rusty with my electrical engineering skills, but I remembered some useful lessons I acquired in the past when I developed an induction heater control unit (unfortunately I have no article for it). What I have is a 5V input signal that turns HIGH whenever the ventilation should start (determined by the dew-point-drying controller). When the signal turn HIGH it need to vent, meaning that the window needs to be opened (LOW pulse on rising edge). After a while when the difference in dew-point becomes too low, the input signal will turn LOW again and the window will be closed (by giving a LOW pulse on the falling edge). The following shows a picture of the schematic that allows is used to control this.

I used a compendium for the impulse generator and boolean algebra for the logic gates. I needed a lot of capacitors on every logic gate output to avoid voltage peaks.

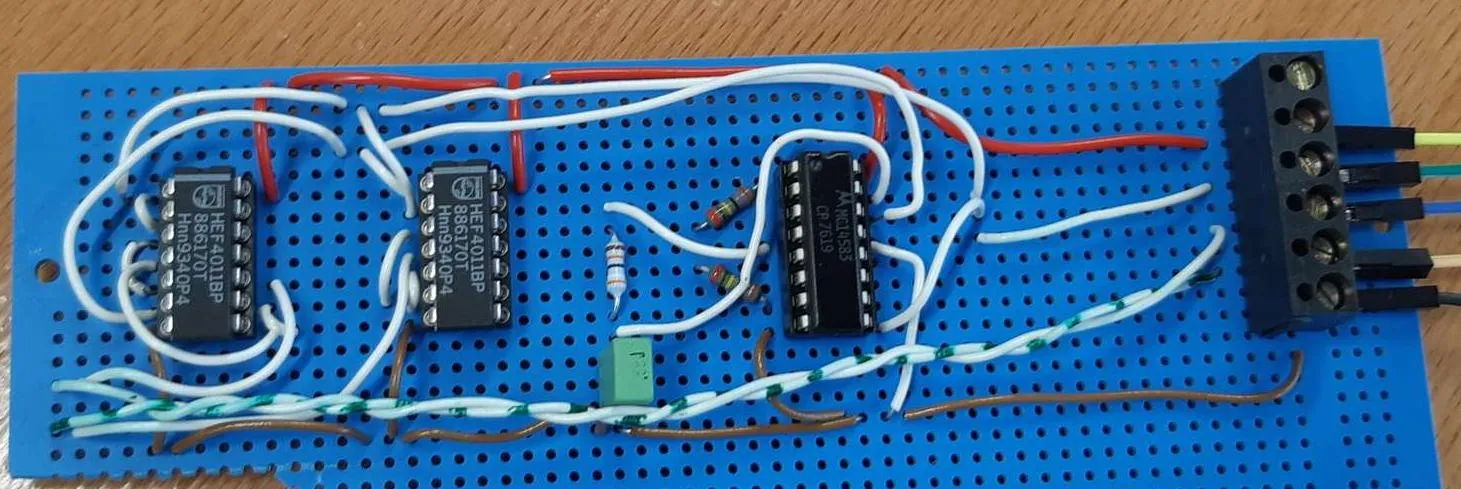

Then I soldered all things together. This is roughly what it looks like now (added more capacitors after picture was taken). I could have used just two ICs, but due to a couple of mistakes during prototyping I made a couple of redundant wires. Nevertheless, it is now operating successfully in the basement.

In the process I made heavy use of the new maker-space in my university. Without their oscilloscopes this would have been impossible, because sometimes chips were broken and the only way to figure out was to measure the signals. Another great benefit was that all the chips used here were stockpiled there. However their names were all MC14-XXX and there was no way of knowing which one I could use. ChatGPT turned out to be incredibly useful in finding the appropriate IC, by asking it for an IC with prefix MC14 and a needed functionality. The tools at the maker space were all ready and top notch. It’s so much more fun to build stuff there, than at home where I have to scavange for parts.